Extreme Duty

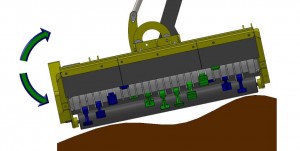

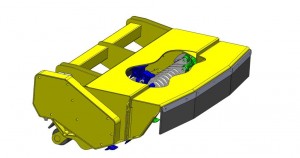

Like all Blaney hedgecutter heads, the extreme duty head incorporates Blaney’s acclaimed power shredding technology. The extreme duty head is developed using more precision components for longer life.

The Extreme Duty head is made using precision manufacturing processes and high precision components for longer life thanks to more accuracy. This ensures less radial and axial loading on drive components for higher speeds, better performance, longer life and lower maintenance.

The body of the Extreme Duty head is 25% stronger than our Heavy duty head.

Cutting Head

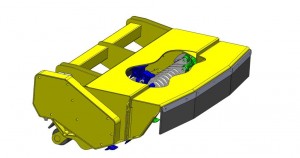

The hedgecutter head is the part of the machine that does the majority of the work and so Blaney Agri have invested much time and resources on its development.

The hedgecutter head is the part of the machine that does the majority of the work and so Blaney Agri have invested much time and resources on its development.

Features and benefits include:

- Flail Heads have a unique heavy duty, twin skinned molecular body for improved strength and reliability. This molecular structure increases strength for longer life.

- Alloy material for minimum weight to increase stability at reach.

- Bearing enclosed within the width of the skid, allowing the head to cut tighter around obstacles.

- High wear front and rear flap for protection against damage from projectiles.

- Offset head for adjustment of reach as and when needed

- 252o angular rotation of cutting head enhances cutting range

- Compact head mount linkage, to cut closer around telegraph poles, etc

- 1.3m width as standard

Bi-Directional Rotor

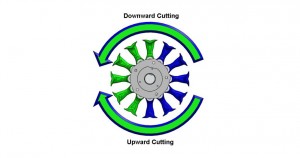

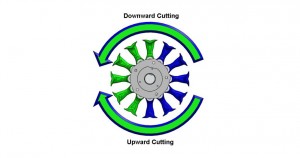

All Blaney Agri hedgecutters are fitted with a bi-directional rotor as standard. The operator can select which way they want the rotor to turn for the task being carried out.

To prevent projectiles being thrown out, it is advised that downward cutting is used, since this throws the debris in the hedge. Upward cutting is more suitable where the material being cut is very dense and a smooth finish is still required.

To prevent projectiles being thrown out, it is advised that downward cutting is used, since this throws the debris in the hedge. Upward cutting is more suitable where the material being cut is very dense and a smooth finish is still required.

The Agri Pro is equipped with a heavy duty rotor as standard.

Arm

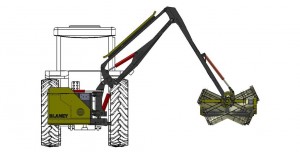

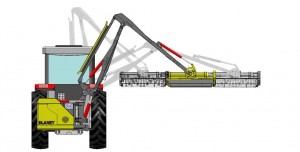

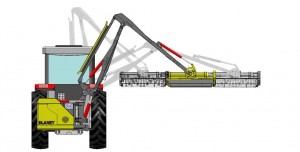

The Agri Pro comes equipped with a standard arm, reaching 4.5m – 5.5m, parallel arm geometry and power slew with hydraulic break back.

Parallel Arm

The parallel arm ensure the Agri Pro Series hedgecutter maintains a consistent head height, while the operator varies the reach of the machine, via a single service input.

Benefits

-Reduces operator fatigue as only 1 service input is required to maintain head height.

-Geometry enhances reach capacity for improved ‘over fence’ clearance.

Safety Breakaway

A safety breakaway system is incorporated into the Agri Pro hedgecutter arm with hydraulic breakback. The function is to protect the arm from damage (typically bending) when the cutting head comes into contact with a foreign object. The arm is allowed to fold back slightly, while the operator brings the tractor to rest, preventing any damage.

Benefits

-Machine arm is protected from damage if the cutting head hits a foreign object

-Tractor is protected from damage that could result from the cutting head hitting an obstacle.

-The obstacle is protected from damage

-A patent pending design to tackle hedges along tight roads and laneways.

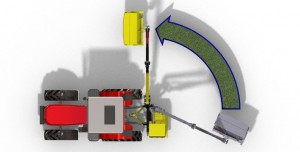

Power Slew

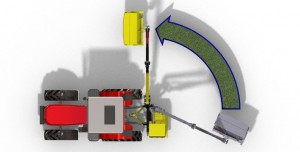

This feature allows the main arm to hydraulically rotate back behind the tractor by 115o.

Benefits

-Provides a compact position for road travel and access through gateways.

-Enables the operator to cut behind into tight corners, without leaving bits behind

-Improves weight distribution of the hedgecutter during transport.

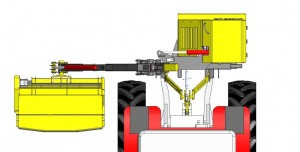

Hydraulic Tank

A 185L Hydraulic tank comes as standard on the Agri Pro Series.

Cable Control

Cable control gives progressive control over the movement of the cutting head. Individual levers for every function means that it is a very user friendly method of control with high sensitivity.

Other features

- Self lubricating pins for optimum greasing

- High capacity bearings for long life

Since Blaney Agri can custom build a hedgecutter an manufacture it to your spec, there’s sure to be a hedgecutter to suit you.

Since Blaney Agri can custom build a hedgecutter an manufacture it to your spec, there’s sure to be a hedgecutter to suit you.

The hedgecutter head is the part of the machine that does the majority of the work and so Blaney Agri have invested much time and resources on its development.

The hedgecutter head is the part of the machine that does the majority of the work and so Blaney Agri have invested much time and resources on its development.

d in-front of the centreline of the main arm, bringing it into the line of sight of the operator, reducing fatigue and increasing performance.

d in-front of the centreline of the main arm, bringing it into the line of sight of the operator, reducing fatigue and increasing performance.